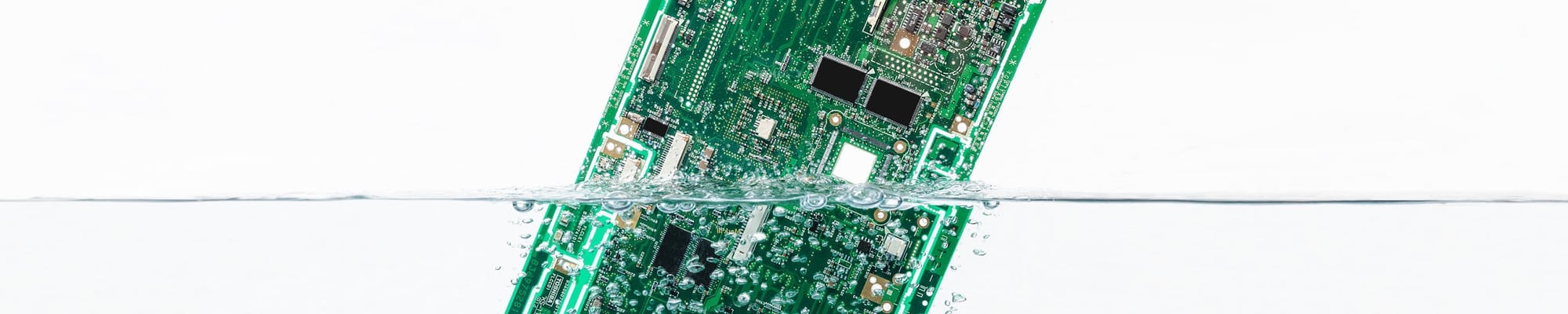

PCB Defluxing and Cleaning

Printed circuit board cleaning for high-reliability applications

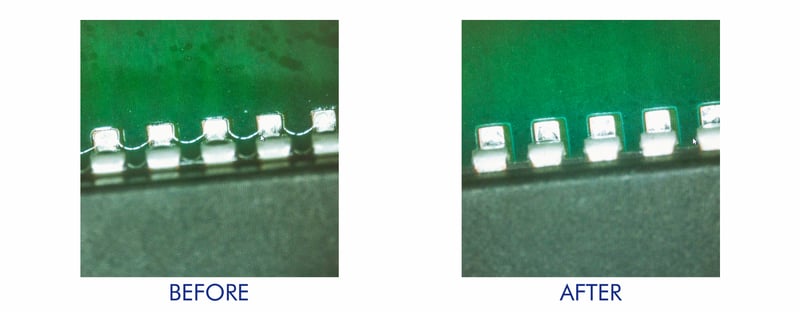

Failure is not an option! When you are manufacturing electronic circuits that are used in high reliability applications, field failures resulting from dendritic growth, electrochemical migration and leakage current among others are unacceptable risks.

At ZESTRON, cleaning agents are powered by technology. We deliver:

- Compatible electronics cleaning and defluxing solutions

- Comprehensive process solutions that are tailored to your unique needs

- A commitment to providing the latest solutions through our continual investment in R&D

The result: you can be assured that your cleaning process is optimized to stay ahead of the latest printed circuit board technology.

Precision PCB Cleaning: Innovative Cleaning Agents and Technical Expertise

Finding the right cleaning product is critical. High precision cleaning requires more than just a chemical solution as today’s printed circuit boards are incredibly challenging to clean due to:

- Smaller components

- Increased board density

- Lower component standoff heights

- Stacked and complex component types

- Increased use of sensitive materials

Our engineering team provides a complete solution offering more than just a product. We help you to better manage and measure your performance, and control your costs. Using industry leading equipment in our Technical Center, you can conduct cleaning trials to determine the best solution for your cleaning challenges. ZESTRON's full-service Technical Center and Analytical Centers enable clients to test PCB cleaning solutions in our facility offering a seamless implementation in your facility.

Defluxing in Sensitive Environments