Prevent risks before they occur.

Do you face particular challenges when monitoring the cleanliness of your electronic components.

1 I RISK ASSESSMENT OF PARTICLES ON ELECTRONIC ASSEMBLIES

Risk assessment Technical Cleanliness:

We analyze for you the safety of your assemblies against short circuits and impairment of the insulation coordination triggered by conductive particles

You select the corresponding degree of contamination based on the short-circuit risk determined

2 I RISK ASSESSMENT LEAKAGE CURRENT AND CONDENSATION

Risk assessment leakage current/condensation:

The hygroscopy and thus the increase in the risk of condensation due to ionic contamination is estimated for you by ion chromatography*

The last results will assist you in making decisions on the topics of degree of contamination, cleanliness and coating.

3 I CONFORMAL COATING:VALIDATION & ROUTINE TESTING

Coating Validation:

By means of the CoRe test & iodine vapor test, we analyze if the coating successfully neutralises the particle and if the protective effect of the coating is given accordingly.

We develop recommendations for you for the improvement of your coating process.

Maximum humidity robustness for components

Understanding risks. Avoiding defects.

Do you have challenges with failing assemblies in the field? Your assembly is still in the design phase and you want to identify possible weak points?.

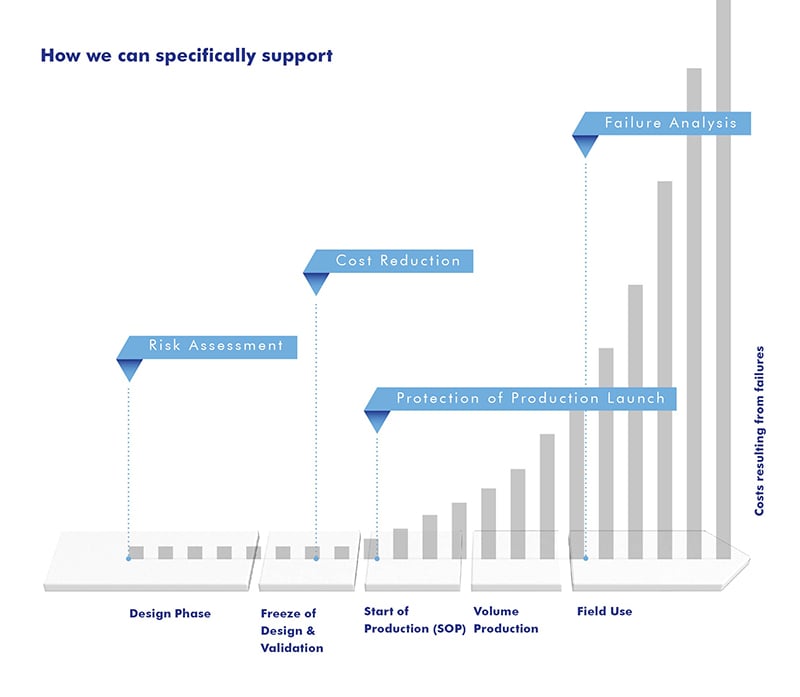

The ZESTRON Reliability & Surfaces team supports you along the entire value chain of electronics manufacturing. Our experts not only evaluate the risk of failure of assemblies and functional units preventively. They also analyze failures in validation tests and damage in the field, both with regard to the mechanism and the underlying causes. Based on this, specific solutions are developed.

✓ Risk Assessment

Additional methods for identifying weak points

✓ Cost Reduction

Evaluation of reliability tests with regard to potential savings in processes and purchased parts

✓ Protection of Production Launch

Proof of compliance with the specifications at the start of serial production

✓ Failure Analysis

Development of sustainable, cost-optimized remedial measures

➞ The earlier weak points are identified and eliminated in the assembly's production process and processes optimized, the lower the costs.

Typical causes of failure for assemblies and functional units

We know the typical causes of failure for assemblies and functional units caused by moisture, contamination and particles. Their explicit identification is the key to remedial measures. Our experienced analytics team has processed more than 1000 cases and has the highest quality analytical equipment at its disposal. In this way, it quickly and flexibly conducts a detailed risk, failure as well as root cause analysis and develops corrective measures. Rely on our competence and experience.

We advise. You benefit.

✓ Specific, economically feasible recommendations for action in the system context.

✓ Confidential and systematic approach – NDA if needed.

✓ Close exchange with our experienced team

✓ Analytics or system discussion – as required